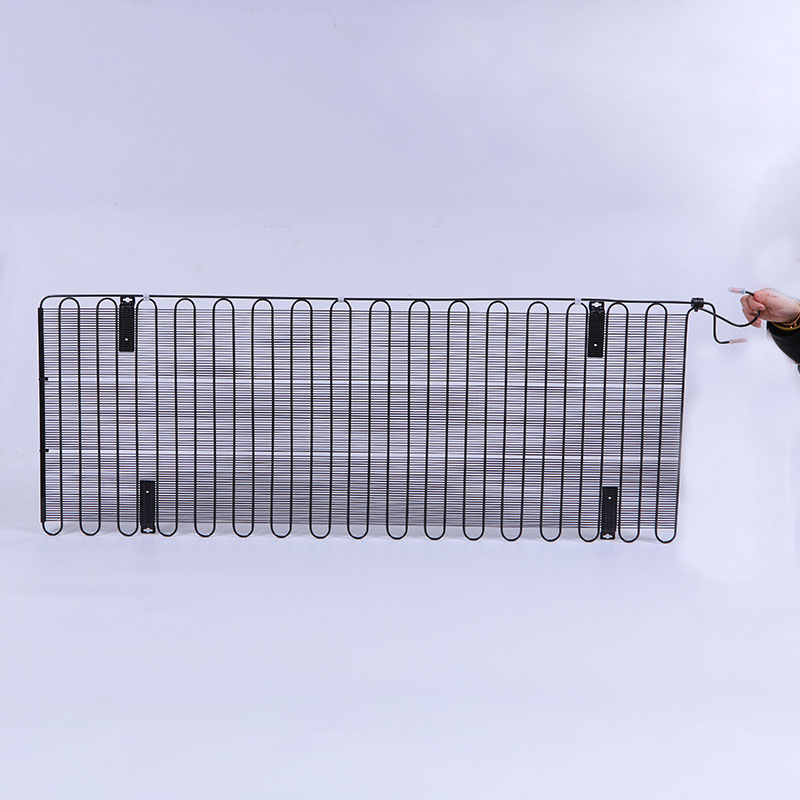

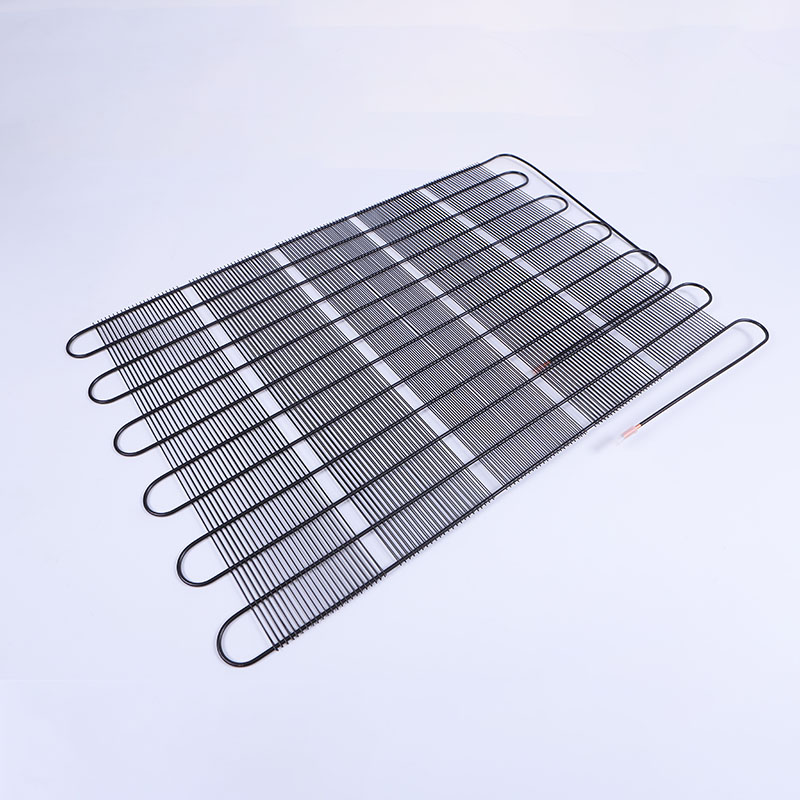

Wire tube condenser bakeng sa sehatsetsi

Re na le taolo e tiileng ea boleng ba welding ea boleng:

1. Matla a tjheseletsa a terata ya tshepe ha a na ho ba ka tlase ho 100N.

2. Kakaretso ea palo ea terata le li-solder tsa bohata li ke ke tsa feta 5 ‰ ea palo eohle ea lihlopha tsa solder; Lintlha tsa ho tjheseletsa lipheletsong tse peli tsa terata ea tšepe le lintlha tsohle tsa ho tjheseletsa moeling o ka ntle oa terata ea tšepe ea condenser ha li lumelloe ho tima kapa ho ts'oaroa hampe; Mohala o tšoanang oa tšepe ha o lumelloe ho ba le lintlha tse peli kapa ho feta tse latellanang tsa welding kapa welding ea bohata.

Sebaka se ka holimo se tšoaroa ka cathodic electrophoretic coating, e nang le ts'ebetso e ntle ea ho hanyetsa kutu, ho netefatsa hore condenser e ka boloka ts'ebetso e tsitsitseng ka nako e telele esita le libakeng tse mongobo le tse senyang. Hape re laola ka tieo bohloeki ba ka hare ho fihlela litlhoko tsa R134a le litsamaiso tsa ho pholisa tsa CFC, ho netefatsa hore ho na le liphello tse ntle le tse baballang tikoloho.

| Litekanyetso tsa tube tsa R134a-cooling-system | |

| Mongobo o setseng | ≤ 5mg/100cm³ |

| Ho se hloeke ho setseng | ≤ 10mg/100cm³ |

| Oli e setseng ea liminerale | ≤ 100mg/100cm³ |

| Chlorine e setseng | ≤5vloppm |

| Parafine e setseng | ≤3mg/cm³ |

Li-wire tube condenser bakeng sa lihatsetsi li sebelisoa haholo maemong a fapaneng, joalo ka mabenkele a maholo, mabenkele a bonolo le lireschorente, ho boloka bohloeki le tatso ea lijo le lino, e le ho ntlafatsa khotsofalo ea bareki. Ka nako e ts'oanang, e boetse e loketse lihatsetsi tsa malapa, tse fanang ka tharollo e sebetsang hantle ea ho pholisa, ho boloka matla le ho boloka tikoloho, ho etsa hore bophelo ba malapa bo be betere.

Khetha wire tube condenser bakeng sa sehatsetsi sa hau ho fihlela ts'ebetso e ntle ea ho pholile le ho fana ka boiphihlelo bo betere ba mosebelisi!

RoHS ea bundy tube

RoHS ea tšepe e tlase ea carbon